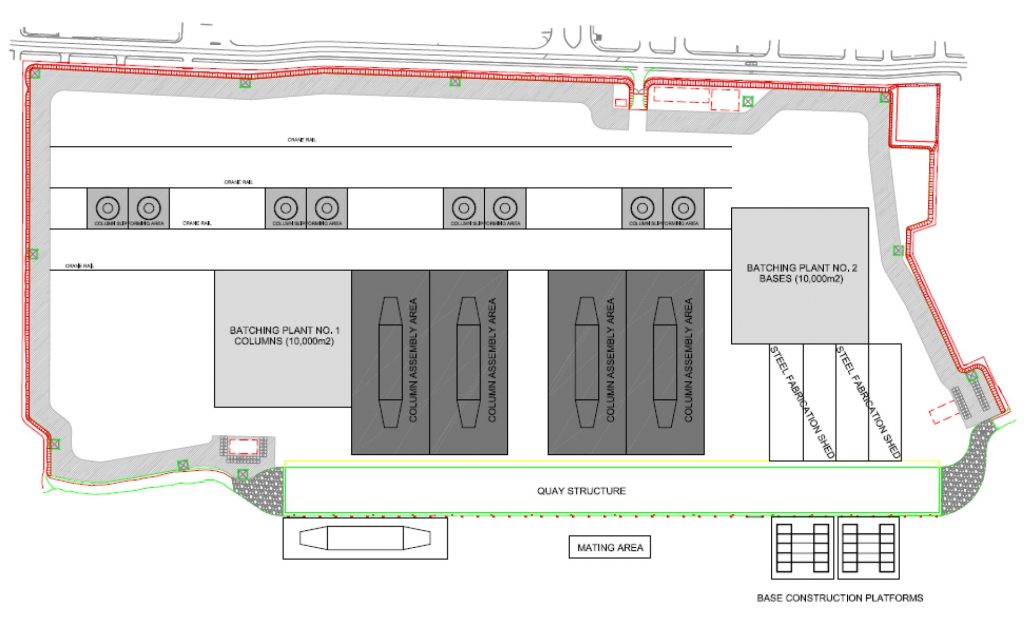

The AWC is designed with local fabrication in mind. The AWC does not need a complex ship yard, dry dock or fabrication facility. A simple fabrication site with a strong quay and reasonable water depth will suffice.

The preferred method to be adopted for base construction involves the use of the so-called Gantry Slipforming Methodology (or floating dock methodology) supported on a pontoon or barge. In this scheme, one or more floating pontoons or barges are moored alongside the quay or at some short distance from the quay.

Construction of the column(s) as two half units. These in turn would be downended and transported to the column assembly area for the joining of the two halves and for post-tensioning.

Downending of the half column sections followed by transport to the column assembly area is relatively short. This is followed, at the column assembly area, by the joining of the two column halves and the post-tensioning of the completed columns. To achieve production of one foundation per week, four columns would be required to be worked on simultaneously.